PRODUCTION

Custom services. We offer machining on state of the art CNC machines, 3D printing with various technologies, quality control with mobile CMMs and reverse engineering including 3D solid model production.

CNC machining

CNC Millings

We offer 4-axis milling services with DOOSAN DNM 5700 machining center:

Table size: 1300 x 570 mm

Max load: 1000 kg

X, Y, Z travels: 1050, 570, 510 mm

4th-axis: Max diameter - 150 mm, length - 100 mm

CNC Turning

We offer turning services with DOOSAN LYNX 220LSY lathe:

Max turning diameter: 200 mm

Max turning length: 510 mm

3D printing

SLA printing

Stereolithography enables extremely precise printing, which results in smooth surfaces. It offers a wide range of materials.

We offer printing on various Formlabs printers:

- Form 3:

Printing volume: 145 x 145 x 185 mm

XY resolution: 25 μm

Layer thickness: 25 - 250 μm - Form 3L:

Printing volume: 300 x 335 x 200 mm

XY resolution: 25 μm

Layer thickness: 25 - 250 μm - Form 2:

Printing volume: 145 x 145 x 175 mm

Laser spot size: 140 μm

Layer thickness: 25 - 100 μm

SLS printing

Selective laser sintering is a powder sintering technology that eliminates the need for supports. Thus, more pieces can be made at once than with other methods.

We offer printing on Formlabs printer:

- Fuse 1:

Printing volume: 165 x 165 x 300 mm

Laser spot size: 200 μm

Layer thickness: 110 μm

Metal printing

Metal powder bound in plastic is printed in layers in the shape of your work. Parts are automatically enlarged to compensate for shrinkage during sintering.

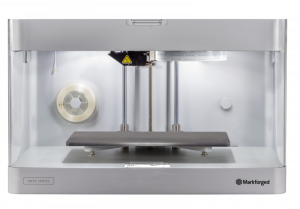

We offer printing on Markforged printer:

- Metal X

Printing volume: 300 x 220 x 180 mm

Z-resolution: 50 - 125 μm

FFF - fused filament fabrication

Najhitrejša in najcenejša metoda 3D tiskanja.

We offer printing on Markforged printers:

- Markforged X7

Printing volume: 330 x 270 x 200 mm

Z-resolution: 50 - 250 μm - Mark Two

Printing volume: 320 x 132 x 154 mm

Z-resolution: 100 - 200 μm

Both printers enable the printing of glass fibers.

Quality control

Portable coordinate measuring machine

Inspection of pieces with a portable CMM from FARO. The arm is movable in 7 axes with the possibility of adding a laser scanner and a rotary table (8-axis). Piece control possible without CAD model. End product is a measurement report.

Arm reach: up to 2,5 m

Accuracy: 0,028 mm

Laser tracker

To ensure the control of pieces at greater distances, we offer the option of using the FARO Vantage Laser Tracker. The laser tracker ensures high accuracy at long distances.

Working area: up to 35 m

Accuracy at 35 m: 0,021 mm

Laser scanner

In the case of larger pieces where the accuracy requirements are not so high, we use the Focus laser scanner from FARO.

Scanning area: up to 70 m

Accuracy: +/- 1 mm at 10 m

Reverse engineering

Portable scanning arm

3D scanning of pieces of different sizes with the aim of obtaining a cloud of points or a mesh model, on the basis of which we create a 3D CAD model. Scanning is performed with a portable measuring arm (7-axis) from FARO with the possibility of scanning on a rotary table (8th axis). The obtained data is then edited in the PolyWorks software environment of Innovmetric.

Arm reach: up to 2,5 m

Accuracy: 0,048 mm

Laser scanner

In the case of larger pieces or spaces, we offer 3D scanning with the Focus scanner from FARO.

Scanning area: up to 70 m

Accuracy: +/- 1 mm at 10 m